VOL.2

Control Valves : Complete Guide to Selection, Maintenance, and Troubleshooting

What Are Control Valves and Why Are They Critical for Industrial Operations?

Control valves are essential components in industrial process control systems that regulate the flow, pressure, temperature, and liquid level of fluids. These precision instruments serve as the final control elements in automated process control loops, directly impacting product quality, energy efficiency, and operational safety.

Modern industrial facilities rely on control valves to maintain optimal process conditions, reduce energy consumption, and ensure consistent product quality. When properly selected and maintained, control valves can significantly improve overall plant efficiency and reduce operational costs.

Common Control Valve Problems and Solutions

1. Control Valve Leakage : Causes and Prevention

Internal Leakage Issues :

- Worn or damaged valve seats and plugs

- Improper valve sizing leading to cavitation damage

- Chemical corrosion affecting sealing surfaces

- Inadequate actuator force causing incomplete closure

External Leakage Problems :

- Deteriorated packing materials

- Improper installation or maintenance procedures

- Thermal cycling causing component expansion/contraction

- Excessive system pressure beyond valve ratings

Prevention Strategies :

- Implement regular inspection schedules

- Use appropriate materials for specific process conditions

- Ensure proper valve sizing during system design

- Maintain optimal packing tension and replacement intervals

2. Cavitation in Control Valves: Understanding and Mitigation

Cavitation occurs when fluid pressure drops below its vapor pressure, creating vapor bubbles that collapse violently when pressure recovers. This phenomenon can cause :

Cavitation Effects :

- Severe erosion damage to valve components

- Noise and vibration issues

- Reduced valve performance and lifespan

- Process instability and control difficulties

Mitigation Techniques :

- Proper valve sizing to minimize pressure differentials

- Use of anti-cavitation valve trims

- Installation of pressure recovery systems

- Selection of cavitation-resistant materials

3. Corrosion Management for Control Valves

Types of Corrosion :

- Chemical corrosion from aggressive process fluids

- Galvanic corrosion between dissimilar metals

- Erosion-corrosion from high-velocity fluids

- Stress corrosion cracking under operational loads

Corrosion Prevention :

- Material selection based on process compatibility

- Protective coatings and surface treatments

- Regular inspection and condition monitoring

- Proper system design to minimize corrosive conditions

Control Valve Selection Criteria

Key Factors for Optimal Performance :

Flow Characteristics :

- Linear vs. equal percentage flow characteristics

- Rangeability requirements for process control

- Pressure drop considerations across the valve

- Flow coefficient (Cv) calculations for proper sizing

Material Considerations :

- Process fluid compatibility and chemical resistance

- Temperature and pressure rating requirements

- Erosion and corrosion resistance properties

- Cost-effectiveness for specific applications

Actuator Selection :

- Pneumatic, electric, or hydraulic actuation options

- Fail-safe requirements and emergency shutdown needs

- Speed of response and positioning accuracy

- Environmental conditions and hazardous area classifications

Advanced Control Valve Technologies

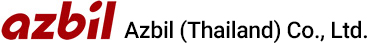

Smart Valve Positioners / Digital Valve Controllers

Modern control valves incorporate intelligent positioners that provide :

- Precise valve positioning and feedback control

- Enhanced control algorithms for improved performance

- Built-in diagnostic capabilities for predictive maintenance

- Advanced diagnostic functions for condition monitoring

- Communication protocols for integration with control systems

- Performance monitoring and trend analysis features

- Integration with plant asset management systems

Maintenance and Diagnostic Services

Preventive Maintenance Programs

Regular Inspection Activities :

- Visual inspection of valve exterior and connections

- Packing adjustment and replacement schedules

- Actuator calibration and performance testing

- Control system integration verification

Performance Testing :

- Stroke time measurements and response testing

- Leakage rate testing per industry standards

- Positioning accuracy and repeatability assessment

- Diagnostic data analysis and trending

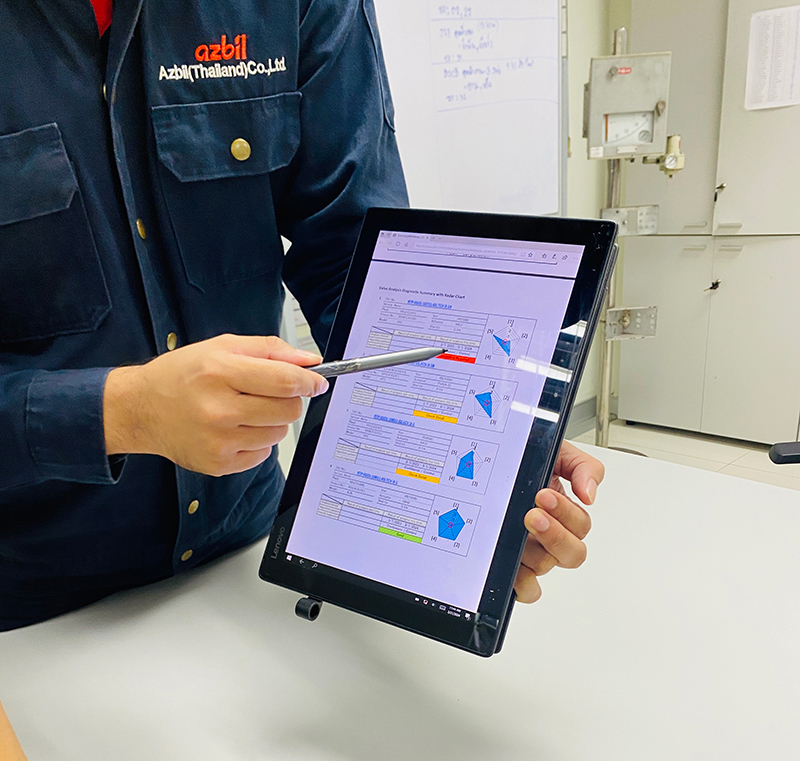

Professional Valve Analysis and Diagnostic Services

Comprehensive valve analysis services include :

- On-site valve performance assessment

- Root cause analysis for operational problems

- Optimization recommendations for improved efficiency

- Training programs for maintenance personnel

Benefits of Professional Diagnostics :

- Extended valve service life through early problem detection

- Reduced unplanned downtime and maintenance costs

- Improved process control and product quality

- Enhanced safety and environmental compliance

Industry-Specific Control Valve Selection Guide

High-Temperature Applications :

- Power generation steam systems

- Petrochemical cracking units

- Metal processing furnaces

- Benefits : Thermal stability, extended service life, safety compliance

High-Pressure Applications :

- Oil & gas pipelines

- Hydraulic systems

- Supercritical processes

- Benefits : Structural integrity, leak-tight operation, system reliability

Corrosive Service Applications :

- Chemical processing

- Marine environments

- Waste treatment

- Benefits : Material longevity, reduced replacement costs, environmental safety

Precision Control Requirements :

- Petrochemical / Chemical processing

- Pharmaceutical manufacturing

- Food processing

- Laboratory systems

- Benefits : Product quality, process repeatability, regulatory compliance

Selecting the Right Control Valve Partner

Key Criteria for Vendor Selection

Technical Expertise :

- Comprehensive product portfolio and customization capabilities

- Application engineering support and system integration

- Advanced manufacturing and quality control processes

- Compliance with international standards and certifications

Service and Support :

- Local technical support and rapid response capabilities

- Comprehensive maintenance and diagnostic services

- Training programs and technical documentation

- Long-term parts availability and lifecycle support

Innovation and Technology :

- Investment in research and development

- Digital transformation and smart valve technologies

- Environmental sustainability and energy efficiency focus

- Continuous improvement and customer feedback integration

Summary : Maximizing Your Control Valve Investment

Control valves are critical components that directly impact your facility's efficiency, safety, and profitability. Key takeaways from this comprehensive guide :

Critical Success Factors :

- Proper Selection : Choosing the right valve type and materials for your specific application prevents costly problems

- Proactive Maintenance : Early detection of abnormal signs that were previously undetectable, preventing sudden failures

- Professional Support : Expert analysis and diagnosis services allow customers to focus on essential maintenance work

Proven Benefits from Azbil's Diagnostic Services :

- Early Problem Detection : Detection of abnormal signs before they affect the process

- Optimized Maintenance Planning : Optimization of maintenance target valve selection during scheduled maintenance periods

- Reduced Troubleshooting : Elimination of analysis and diagnosis work, allowing focus on essential maintenance tasks

- Operational Efficiency : Streamlined post-maintenance testing for faster equipment startup

Real Case Study Results :

- Equipment Failure Prevention : Detection of equipment abnormalities in loops that appeared normal based on control results alone, preventing equipment trouble

- Maintenance Optimization : Identification of valve abnormalities that would have been excluded from TBM (Time-Based Maintenance) targets, contributing to proper maintenance target selection

- Cost Reduction : Significant cost reduction through condition-based maintenance using valve operating data visualization

Contact Azbil Thailand

for Expert Control Valve Solutions

Ready to optimize your control valve performance and achieve measurable results?

Azbil Thailand offers comprehensive control valve solutions backed by decades of industrial expertise and local support.

Why Choose Azbil Thailand?

Industry Expertise :

- Over 100 years of experience in industrial automation

- Deep understanding of Thai industrial market requirements

- Proven track record across chemical, petrochemical, power, and manufacturing sectors

Comprehensive Solutions :

- Complete control valve portfolio from standard to custom applications

- Advanced diagnostic and maintenance services

- Smart valve technologies with predictive maintenance capabilities

Local Support Advantage :

- Thai-speaking technical specialists for immediate support

- Rapid response times for urgent service needs

- On-site training and technical consultation

Our Thailand Services Include

Application Engineering

- Free consultation for valve selection and sizing

- Process optimization studies and recommendations

- Custom valve design for unique applications

Professional Services

- Valve analysis and diagnostic services

- Preventive maintenance programs

- Emergency repair and retrofitting

- Performance optimization consulting

Training and Support

- Technical training for maintenance personnel

- Documentation and technical manuals

Get Started Today

Don't let control valve problems impact your operations. Contact Azbil Thailand's experts to discuss your specific requirements and discover how our solutions can improve your facility's performance.

Request Your Free Consultation

Take the first step toward optimizing your control valve performance :

- Initial Assessment - Our engineers will evaluate your current systems

- Custom Recommendations - Receive tailored solutions for your applications

- Implementation Plan - Get a clear roadmap

- Ongoing Support - Benefit from continuous optimization and maintenance

Ready to improve your control valve performance?

Contact Azbil Thailand today for expert consultation and discover how our proven solutions can deliver measurable results for your facility.

For all enquiries, please feel free to contact us

Click Here