Digital Mass Flow Controller Model F4Q

“I want to automate flow rate control instead of relying on an experienced worker.”

“I want to quickly understand the status of control at the site.”

For this kind of manufacturing issue, Azbil has developed an advanced mass flow controller.

Providing higher visibility, higher accuracy, faster response, lower pressure loss, and a wider temperature range, Azbil’s new advanced mass flow controller is a smart solution for everyday gas flow rate control problems.

“I want to automate flow rate control instead of relying on an experienced worker.”

“I want to quickly understand the status of control at the site.”

For this kind of manufacturing issue, Azbil has developed an advanced mass flow controller.

Providing higher visibility, higher accuracy, faster response, lower pressure loss, and a wider temperature range, Azbil’s new advanced mass flow controller is a smart solution for everyday gas flow rate control problems.

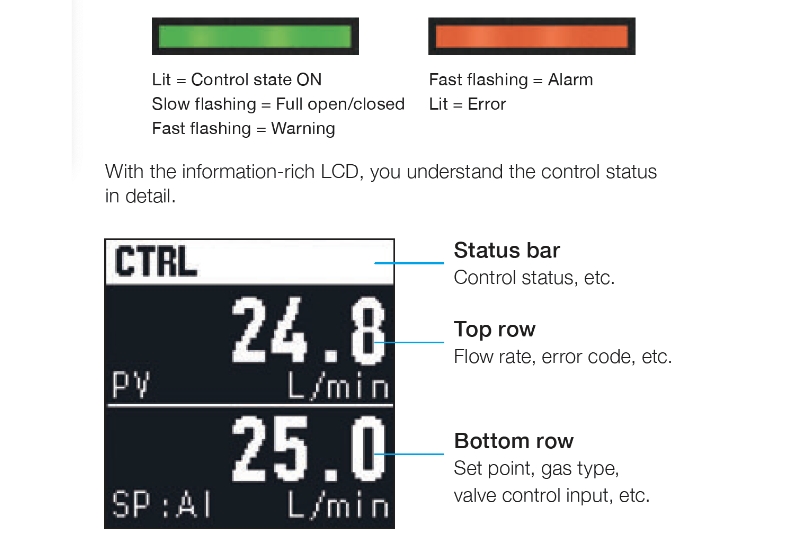

Understand the status of control at a glance

The color and state of the LED indicator (e.g., flashing) show the status of control. With the information-rich LCD, you can understand the situation in detail.

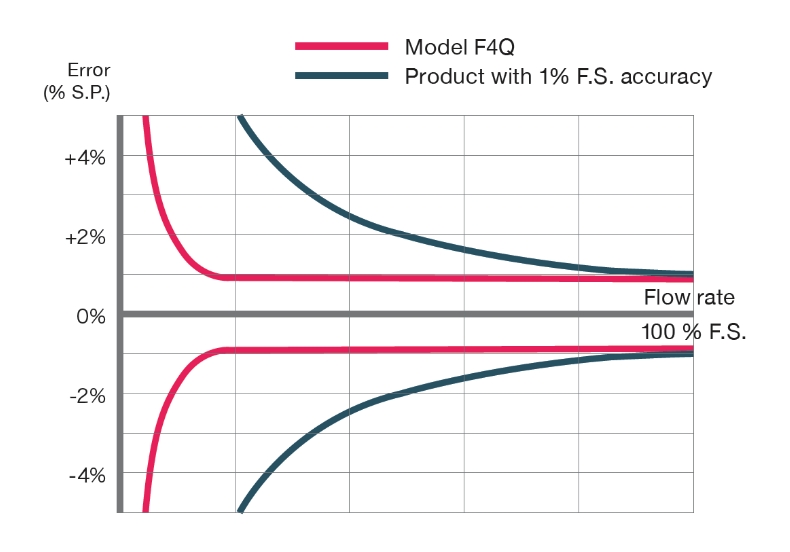

Accuracy of 1% of the set point in a wide range of flow rates

High-accuracy control for high and low flow rates. Great for applications where the flow rate set point changes significantly.

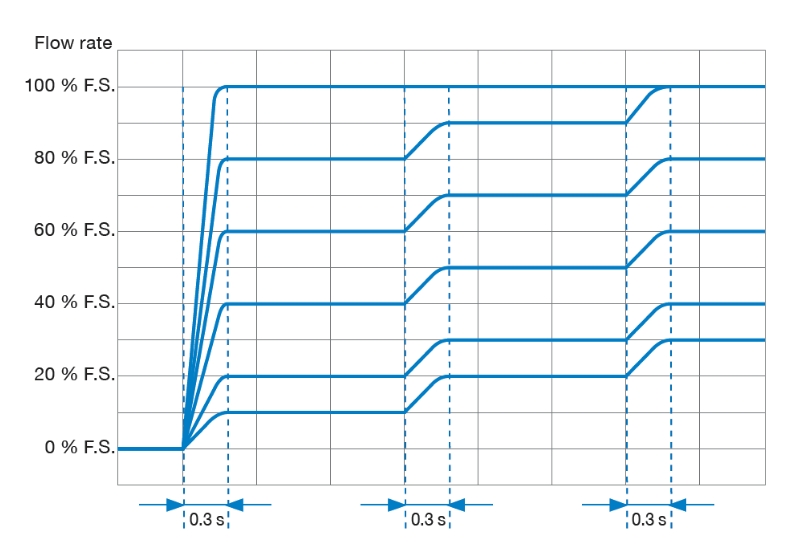

High-speed response of 0.3 seconds over a wide range of flow rates

Response is fast whether starting control with a fully closed valve or changing the settings. Even when the flow rates of multiple gases are changed at the same time, their gas ratios can be retained.

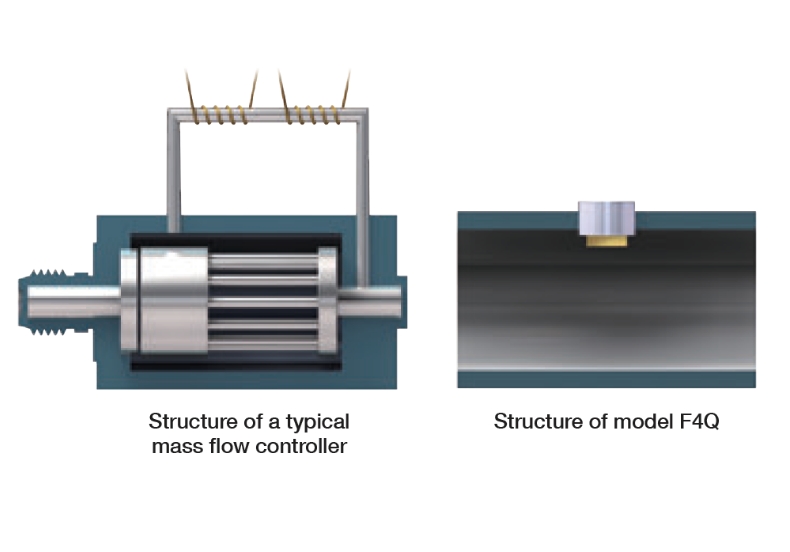

Low differential-pressure structure allows control of low-pressure gas

The pressure loss on a straight flow path is low, so this controller can control low-pressure gas (e.g., fuel gas).

Usable in a wide temperature range, from −10 to +60°C

The controller can be used in a cold room in winter or near a hot industrial furnace. Even when the temperature changes significantly, its effect on the measured values is minimal.

Our digital mass flow controller model F4Q is available for a variety of applications.

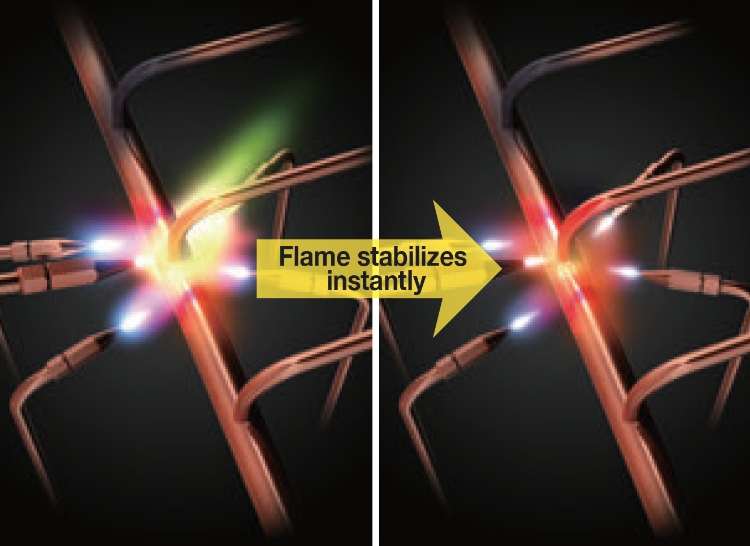

Brazing and burner work

Thanks to the controller’s high-speed response, when the flame intensity changes, the flame instantaneously stabilizes, contributing to stable product quality and reduced takt time.

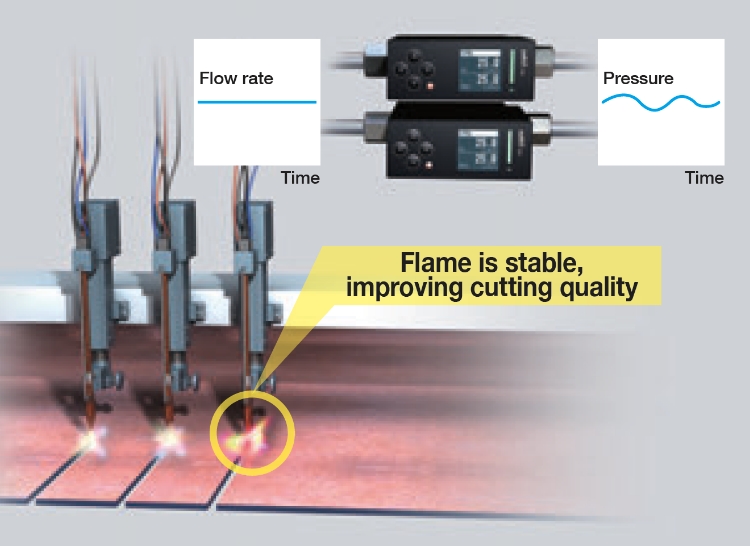

Gas cutting

Thanks to the controller’s high-speed response, even when the source pressure changes, there is very little effect on the flow rate. The flame remains stable, which improves cutting quality.

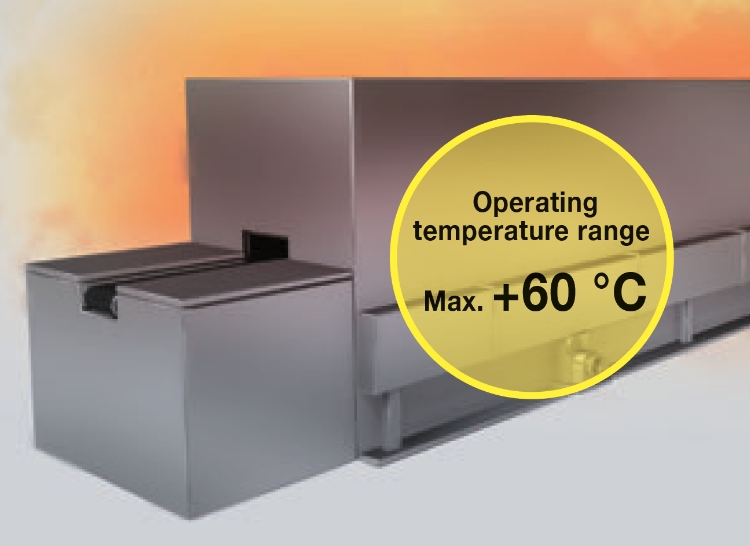

Baking furnace for MLCCs

The operating temperature range is a wide −10 to 60 °C and the effect of ambient temperature changes on flow rate control is small. A stable atmosphere in the furnace also helps to stabilize the quality of baking.

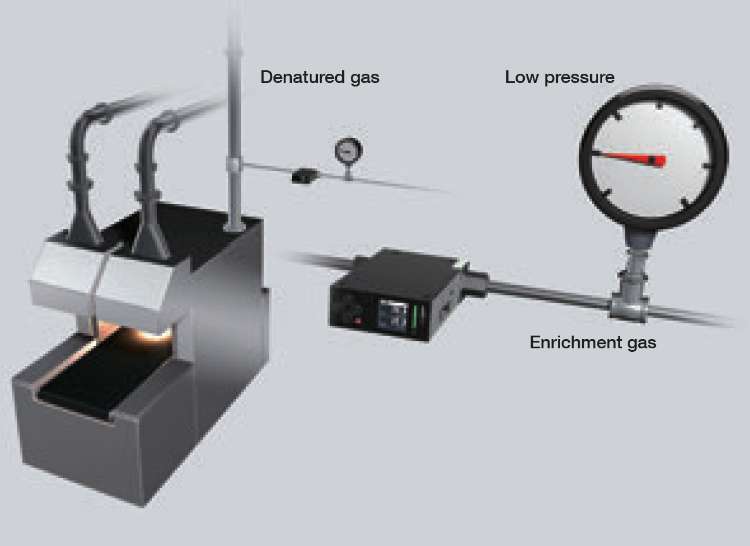

Gas carburizing furnace

Thanks to low pressure loss, model F4Q can control the flow rate of low-pressure enrichment gas, which is not possible with typical mass flow controllers. Better control of the atmosphere in the furnace can stabilize the quality of carburization.

Culture apparatus

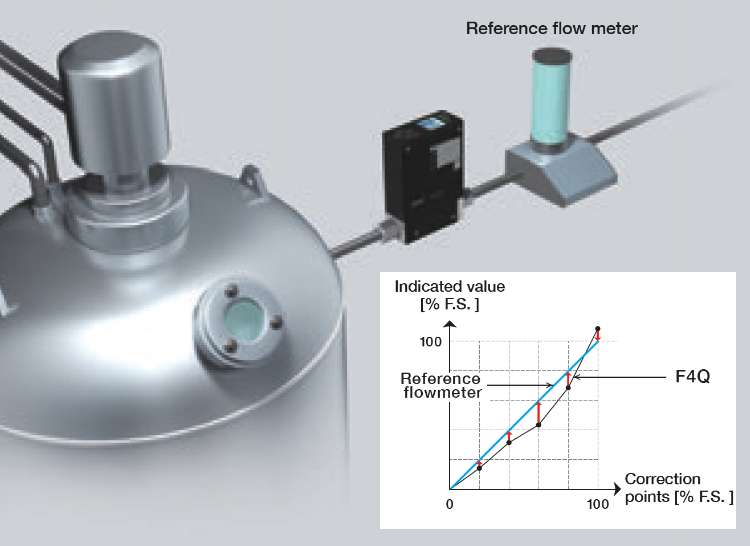

The multiple-point flow rate correction function makes matching to a reference flowmeter possible during onsite calibration. It is not necessary to send the controller to the manufacturer for calibration, so costs can be cut and delivery schedules can be shortened.

Experiments

With an AC adapter, the controller can be powered from a wall socket, eliminating the need for tedious wiring. Operation, monitoring, and data logging from a PC can be done using the PC loader. An experimental environment can be set up in a short period of time.

Free case study collection packed with ideas for solving problems with gas flow rate control

If you wish to download information, please fill out and submit the signup form.

If you wish to download information, please fill out and submit the signup form.