We provide one-stop control valve life cycle solution

which ensures safe plant operation

-

Achieve higher maintenance

efficiency combined

with lower plant operating costs

Smart Valve Positioner

-

-

Digitalization of valve maintenance

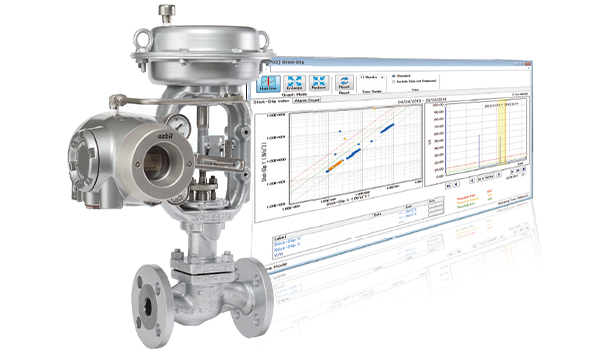

Control valve maintenance support system PLUG-IN Valstaff™

A Fusion of Tradition and Innovation

We provide the best solution

depending on your needs

The azbil Group support the complete manufacturing cycle of the customers by providing a life cycle solution and support system based on the company’s comprehensive maintenance technological capability accumulated since its foundation in 1906.

Start Up

Our easy and speedy initial setting

achieves higher efficiency for safe

and secure plant startup

Operation

We support efficient monitoring

and stable operation to prevent troubles with the control valves

and achieve plant operation without accidents

Turn around

Maintenance

We support customers in maximizing

their facility’s life cycle as well as

improving efficiency and optimizing maintenance

Solution for Start Up

Issues during start up

Time before startup is limited,

but initial setting takes time and effort

Before

Adjustment is time-consuming due to the complex setting of smart positioner

The smart positioner currently used requires to perform from the setting Screen of display according to the prescribed procedure, which takes around 10 minutes to complete

After

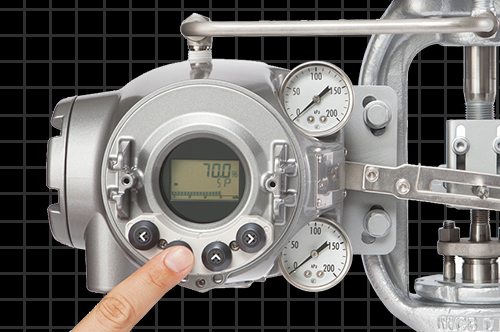

Smart Valve Positioner

Adjustment and setting can be made easily anywhere. The auto setup function completes the time-consuming setting function in 90 seconds

The adjustment and setting system with a combination of LCD and the push buttons installed on the front of the smart valve positioner (Local User Interface (LUI)) allows operation without harming the explosion-proof structure, and the settings can be made quickly.

Adjustment and setting can also be made using a variety of mobile tools or the device management system.

With access from anywhere, including on-site, maintenance shop and operator room, the efficiency of adjustment and setting before operation is improved.

If you would like to know more about Smart Valve Positioners

Issues during start up

Checkup before startup takes many man-hours and days

Before

The conventional checkup before startup requires confirmation by the engineer.

Conventional valve inspection is generally performed one by one by two operators, one in the control room and the other on-site, which requires time and workload.

After

Control valve maintenance support system PLUG-IN Valstaff

Automated inspection of control valve achieves much better efficiency and lower workload.

PULG-IN Valstaff inspects a large number of control valves by one operation, and provides a report on the inspection results, which allows for drastically fewer man-hours required for inspection activity.

Significantly shorter inspection time allows quicker production startup and less downtime.

If you would like to know more about control valve maintenance support system

PLUG-IN Valstaff

Solution for Operation

Issues during operation

Equipment breaks down suddenly,

which affects the plant’s operation

Before

Equipment is likely to break down under severe operating conditions.

Control valves and positioners are expected to keep working for a long time, even under severe operating conditions such as corrosive gas atmosphere in the plant and in coastal areas subject to salt damage. In addition, since these parts are installed in the piping system, they are liable of being exposed to violent vibration. If their pneumatic system are not kept separate from the electrical and electronic parts, the risk of a breakdown is higher.

After

Smart Valve Positioner

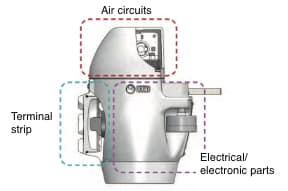

Design reduced the risk of breakdown and achieves excellent durability at the same time

Electrical and electronic parts consisting of the print board, LCD, position sensor and coil are located in an explosion-proof container. The pneumatic air system through which instrument air that may contain oil or water passes, and the terminal block which may contact air containing water and corrosive gas, are located outside the explosion-proof container.

The above structure protects the electrical and electronic parts from risks and improves the reliability of the equipment.

If you would like to know more about Smart Valve Positioners

Issues during operation

Failure to identify problems with equipment earlier

causes trouble with the plant’s operation

Before

It is difficult to notice problems in the control valves before they become obvious.

Any failure of the control valves working at key points in the production process would have an adverse effect to continuity of the plant’s operation and the quality of the products as well as cause trouble for the engineers.

It can be difficult to identify problems in the control valves before they become obvious, such as an unexpected change in the flow rate.

After

Control valve maintenance support system PLUG-IN Valstaff

24/365 monitoring of the control valves operating condition.

Contribution to prevention of sudden troubles during operations.

PULG-IN Valstaff collects from the Smart Valve Positioners the operating data such as variances between the preset positions and the actual positions. It supports improving the efficiency of maintenance by detecting problems in valves earlier and visualizing the necessary information for maintenance related decision-making.

PULG-IN Valstaff quantifies the status of the control valves that used to be invisible, and supports early detection of problems and prevention of unscheduled equipment failure.

If you would like to know more about Control Valve Maintenance Support System

PLUG-IN Valstaff

Issues during operation

Unexpected troubles affect the production

and quality of the products.

Before

There is no way to recognize that the inside of the control valves is in bad condition. Therefore, unnecessary maintenance is often held for the control valves with good condition.

As there is no way to know the condition of the inside of the control valves, the scope of maintenance is generally determined based on a period of time, not the actual condition of the control valves.

As such, control valves that are in good condition may be selected for maintenance, or damaged valves may not be inspected before a restart that subsequently causes trouble.

After

Smart Valve Positioner

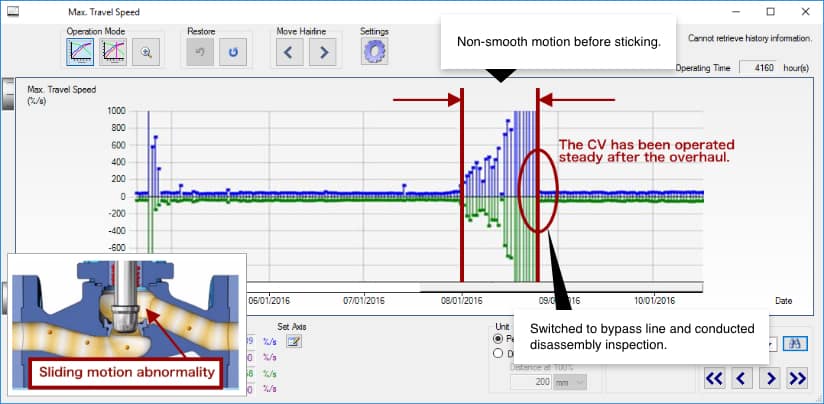

Control valve maintenance support system PLUG-IN Valstaff

The status of the control valves can be identified from data collected by the Smart Valve Positioners while operating.

Analyzing and diagnosing the data collected by the PULG-IN Valstaff allows early detection and projection of trouble in each part of the valves while the plant is operating, which contributes to prevent equipment stoppage caused by faulty valves.

We propose a systematic and effective maintenance plan based on the condition of the control valves, and we support customers in developing the maintenance plan.

If you would like to know more about Smart Valve Positioners and/or

the Control valve maintenance support system PLUG-IN Valstaff

Solution for

turn around maintenance

Solution and Technology Center

We provide consulting services from the perspective of an experienced specialist of control valve inspection

At the Solution and Technology Center in Rayong, Thailand, we listen carefully to each customer’s requirements and problems in plant operation and propose the best solution. Our latest automation products and services are available in the local language.

In addition, in collaboration with the Strategic Planning & Development Office for Southeast Asia and Fujisawa Technology Center (Japan), we provide support by experienced specialists of control valve inspection services.

Furthermore, at the showroom, you may try our state-of-the-art product technologies and consider installation of IoT or AI-based next-generation solutions.

Showroom

- Field Instrument, Smart Valve Positioner, Control Valve and ESD Valve demonstration unit.

- DCS (Harmonas-DEO™), InnovativeField Organizer™/PULG-IN Valstaff and Early Warning System for Time Series Data

To Start Up

azbil Group

We work closely with the customers at their work site and create the best value solution depending on the local situation.

Driven by the Group philosophy of “human-centered automation,” the azbil Group strives to utilize its measurement and control technologies to realize safety, comfort, and fulfillment in people’s lives while contributing to the global environment. Furthermore, through expanding the business globally, we have established local bases for development, production, and service so that we can deal with the needs for automation which vary depending on the weather, climate and culture of each country.

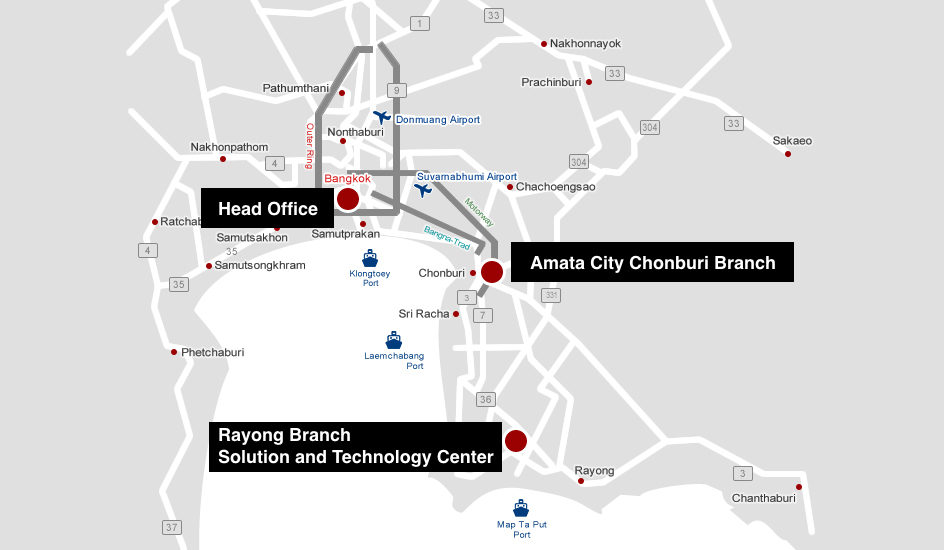

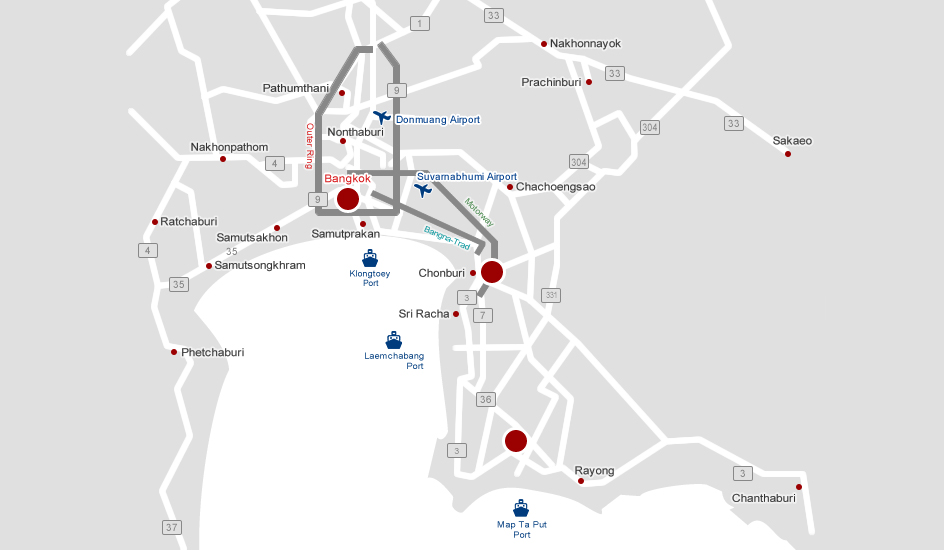

Company Profile

Azbil (Thailand) Co., Ltd.

Head Office

-

Address

No.9 G Tower Grand Praram 9, 14th Floor, Rama 9 Road, Huay Kwang, Huay Kwang, Bangkok 10310

-

TEL

-

FAX

+662-011-9011~3

Amata City Chonburi Branch

-

Address

Amata Service Center Building Unit No. 401, 4th Floor, 700/2 Moo 1 Amata City Chonburi Industrial Estate, Bangna-Trad Km.57 Road, T.Klong Tumru, A.Muang, Chonburi 20000

-

TEL

-

FAX

+6638-457-078

Rayong Branch

Solution and Technology Center

PLUG-IN Valstaff, Harmonas-DEO, InnovativeField Organizer are trademarks of Azbil Corporation