Industrial Systems

Products

Solution & Services

01

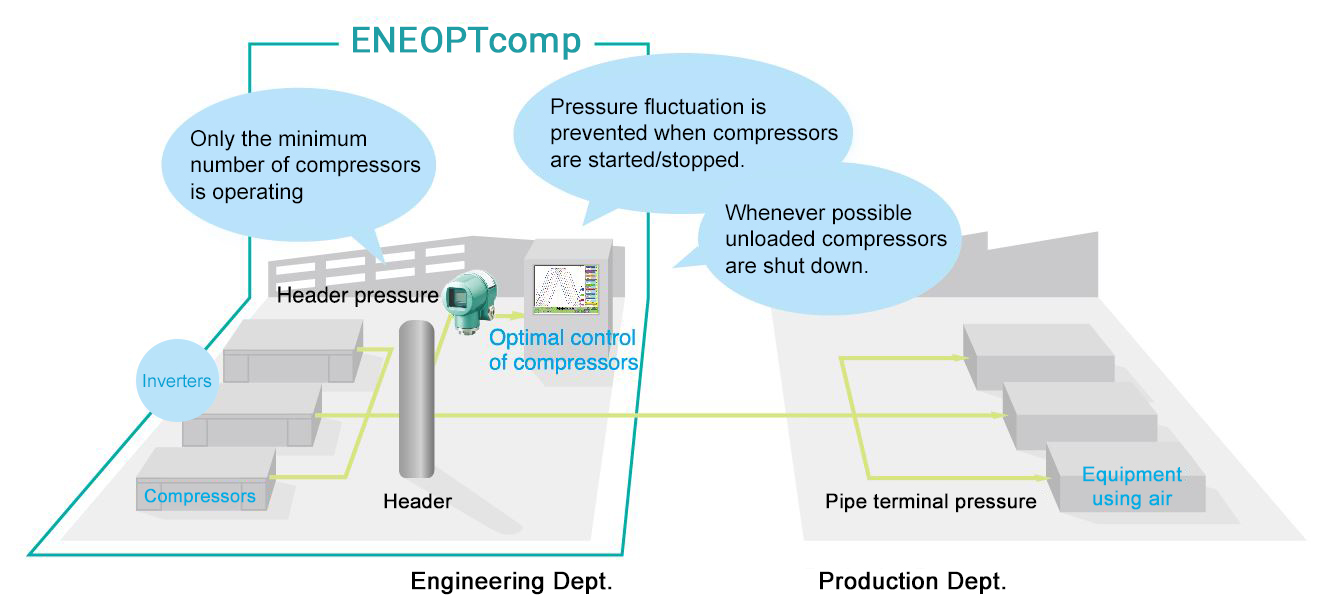

Harmonas-DEO™

Harmonas-DEO is a next-generation operation monitoring and control system that serves as the nerve center for data-driven smart factories in the age of IoT. Through links to Azbil's proprietary online malfunction-prediction system, which makes use of AI (artificial intelligence), and to a system for utilizing monitoring and diagnostic data from individual smart devices, Harmonas-DEO provides data-based monitoring.

In addition, the enhanced operability and visibility of the human-machine interface (HMI) during operation monitoring promotes safer and more reliable operation.

Harmonas-DEO is Azbil's newest DCS compatible with the existing Azbil's DCS.

(*)Harmonas-DEO is a trademark of Azbil Corporation.

System Configuration

The Harmonas-DEO system includes an HMI for monitoring and operation, such as a supervisory station, and a highly reliable, redundancy-capable controller connected by a redundant Ethernet control network.

The operation and monitoring environment provided by the HMI supports prompt situational awareness and swift comprehension and decision-making, and provides operators with guidance for correct use.

02

Hardware manufacturing,

Software implementation and

Factory Acceptance Test

Software implementation and

Factory Acceptance Test

We provides cabinet/panel manufacturing based on the hardware Manufacturing Drawings at our factory near Bangkok. We provide software implementation service, i.e. data base generation, sequence programming logic, graphic display and report.

03Site startup service and

System Maintenance Program

Ensure a seamless DCS site startup with our expert commissioning and system integration services.

Our experienced engineers handle everything frominstallation, configuration, and functional testing to system optimization, ensuring a smooth transition to full-scale operation.

We work closely with your team to minimize risks, enhance reliability, and maximize system efficiency.

Beyond startup, our comprehensive DCS maintenance programs keep your system running at peak performance.

We offer preventive maintenance, real-time breakdown maintenance, and customer site support services to reduce downtime and improve system longevity.

Our parts management program ensures you have the right components when needed, avoiding costly delays and unplanned outages.

With our proactive approach to DCS maintenance and lifecycle support, you can enhance system stability, optimize performance, and extend equipment lifespan.

04Training

Unlock the full potential of your Distributed Control System (DCS) with our specialized training programs. applications.

We offer three tailored courses:

- Operation Course

- Maintenance Course

- Engineering Course

These 3 designed courses to enhance your team's expertise and improve plant efficiency.

Whether you need to master system operations, troubleshoot and maintain equipment, or develop advanced engineering skills, our expert-led training ensures hands-on experience and real-world.

Empower your workforce with the knowledge to maximize system performance, reduce downtime, and optimize processes.

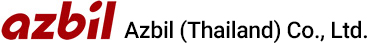

azbil Group Targets for CO2 Emission Reduction

Initiatives to Achieve the SDGs: Preserving the Earth’s Environment and SolvingEnergy-related Problems through “Cooperative Creation”

Total annual effective reduction of CO2 at customer's sites for fiscal year 2021 (ended March 2022) was 2.94 million metric tons. This corresponds to approximately 1/400 of the total CO2 emitted in Japan each year(approx. 1.2 billion metric tons).

Targets by fiscal year 2030 (ended March 2031)

Effective reduction of CO2 at customer’s site : 3.4 million metric tons of CO2

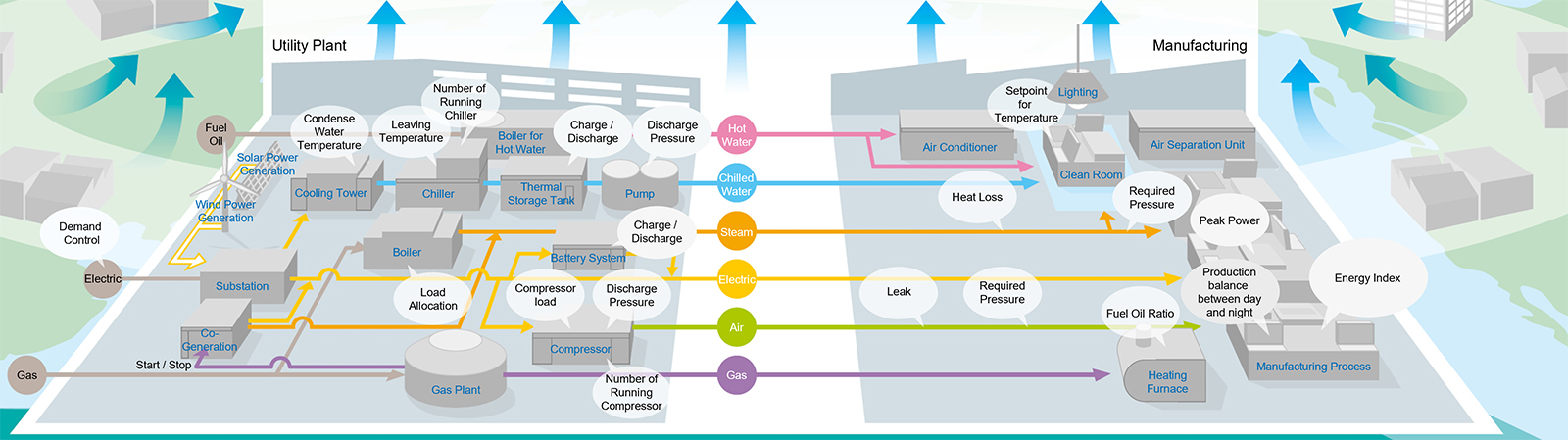

Solution Service for Energy Conservation

Discussion with Customer to find the Opportunity for Energy Saving By Operation Improvement

Calculate the CO2 emissions reduction, Overall Energy Efficiency improvement, Energy Saving

Design Documents Implementation ,Testing and Training Commissioning to check Energy Saving

Performance check and Reporting. Tuning for Optimization Control.Propose further improvement